Prefacio

The basic currency of a safe and working boat dock is stability. The main issue facing the waterfront property owners and the maritime operators is how to reduce the constant sway and roll of the water due to the boat wakes, wind loading and changing currents.

It takes more than simply adding extra weight to achieve a rock-solid platform; it is a calculated combination of hydrostatic physics and structural geometry. This manual is a technical roadmap to the art of dock stabilization, the simple distribution of loads to the sophisticated modular engineering, so that each step onto the water is made with confidence and security.

¿Qué es un dique flotante?

Un dique flotante es una construcción diseñada para ser colocada sobre el agua y anclada a la orilla o sumergida en el agua. Son muelles que se construyen sobre el agua y tienen la capacidad de cambiar su altura en relación con el nivel del agua de la masa de agua, por lo que facilitan el acceso a las embarcaciones. Los diques flotantes pueden fabricarse con tablones de madera, metales ligeros y plástico, y pueden equiparse con accesorios en función de la finalidad del dique.

Los diques flotantes son los preferidos en puertos deportivos y atracaderos privados, ya que son más cómodos de construir y mantener que los fijos. Pueden utilizarse en aguas tranquilas, fluviales y marítimas.

Why Floating Docks Sway: Technical Diagnosis

In order to resolve the instability, it is necessary to go beyond superficial solutions and conduct a technical analysis of the particular environmental, geometrical, and physical forces that determine the response of a platform to the water.

The External Forces

Stability usually does not work since the dock is not able to dissipate energy. The sudden bursts of kinetic energy are caused by boat wakes, and the lateral pressure caused by river currents can lead to fishes tailing. High profile metal structures, such as railings or canopies are subjected to wind loading, which causes a heeling moment, and the tension in the docking system varies with tidal changes, causing temporary instability.

Structural Geometry

The size of a dock determines its stability. A bad Aspect Ratio, like a long, narrow arrangement, is one that has a broad enough base to create a restorative moment. Moreover, the distribution of added flotation is essential; excessive buoyancy of docks may make them twitchy, whereas sparse flotation leaves dead spots that sink when the user shifts to one side.

The Physics of the G-B Interaction

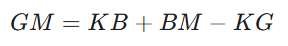

The relationship between the Center of Gravity (G) and the Center of Buoyancy (B), namely, the Metacentric Height (GM), defines true stability.

- Positive GM: The dock will automatically produce the torque required to reposition itself at a level position.

- The Formula:

KG is the height of the center of gravity, KB is the height of the center of buoyancy and BM is the metacentric radius calculated by the width of the dock.

The Buoyancy Paradox: The Cork Effect

One of the most frequent errors is to think that the higher the buoyancy, the higher the stability. In practice, over-buoyant docks are afflicted with the Cork Effect in which they exert no grip whatever on the fluid and respond violently to any ripple. To achieve Hydrodynamic Damping, the correct balance a lightweight mass with enough draft must be found to enable engineering of a stable dock. The amount of weight you can carry is determined by buoyancy, and the amount of stability is determined by the draft (depth below the waterline).

Factores que afectan a la estabilidad de los diques flotantes

En el diseño de diques flotantes, varios factores pueden influir en su estabilidad en el agua. A continuación se describen en detalle los principales factores:

- Profundidad del agua

La profundidad del agua donde se coloca el muelle es un factor que afecta en mayor medida a la estabilidad del mismo. Por ejemplo, los muelles construidos en aguas más profundas pueden requerir postes de anclaje más largos y flotadores más resistentes para evitar que la estructura vuelque.

- Acción de las olas

La energía y la frecuencia con que las olas golpean el muelle. Las olas más grandes y frecuentes provocan más movimiento y pueden requerir más apoyo, como anclajes más fuertes o rompeolas.

- Cambios en el nivel del agua

Factores como las mareas, los cambios de estación o incluso los cambios meteorológicos son algunos de los factores que provocan cambios en el nivel del agua. Las fluctuaciones del nivel del agua pueden ejercer una fuerza adicional sobre los sistemas de anclaje y flotación del muelle, por lo que exigen componentes que puedan modificarse.

- Calidad del material

El tipo de construcción y el tipo de material que se ha utilizado en la construcción del dique. El plástico es preferible para los diques flotantes porque es ligero, no se corroe ni se pudre con facilidad. Es más duradero, no requiere mantenimiento frecuente y puede soportar condiciones desfavorables en comparación con materiales como la madera o el metal.

- Distribución del peso

La distribución del peso sobre la superficie del muelle. Un desequilibrio en el peso puede provocar vuelcos y tambaleos. Para ello, el peso debe repartirse uniformemente para no ejercer presión sobre un lado u otro.

- Sistema de anclaje

El tipo de sistema de anclaje utilizado para asegurar el muelle, y la calidad del sistema utilizado. Debe emplearse un sistema de anclaje que incluya postes de anclaje, anclajes de peso muerto y pilotes para reducir el movimiento y mejorar la estabilidad.

- Diseño de muelles

El diseño general y la construcción del muelle en particular. Un buen muelle es el que tiene una base estable, una buena flotabilidad y un peso bien distribuido harán que el muelle sea más estable. Otras características que también pueden utilizarse para aumentar la estabilidad son los estabilizadores o las pasarelas.

- Condiciones medioambientales

Las condiciones del entorno en el que se encuentra el dique: viento, caudal de agua y temperatura. Los factores ambientales también pueden afectar al muelle y hacerlo más vulnerable al desgaste. Por eso es necesario elegir los materiales y diseños adecuados a estas condiciones para conseguir estabilidad.

- Mantenimiento e inspección

El mantenimiento y la inspección del muelle y de sus piezas de forma correcta y periódica. El mantenimiento también implica comprobaciones periódicas del muelle para ver si está desgastado, corroído o dañado de algún modo, de modo que pueda repararse o sustituirse para evitar que se convierta en un peligro para los usuarios.

- Normativa local

Se siguen los requisitos legales para garantizar que la construcción del muelle cumple las normas de seguridad y estabilidad establecidas, reduciendo así la probabilidad de que la estructura se derrumbe.

The Floating Dock Stabilizer Kits

| Componente | Función | Características |

| Postes de anclaje | Fije el muelle al fondo del lago o al lecho marino, evitando movimientos excesivos. | Fabricado con materiales duraderos como acero inoxidable o madera tratada. Ajustable a la profundidad del agua. |

| Dispositivos de flotación | Proporcionar flotabilidad adicional al muelle. | Fabricado en polietileno de alta densidad. Ligero, duradero y fácil de instalar. |

| Anclas de muelle | Asegure el muelle en su lugar, minimizando el movimiento lateral. | Varios tipos, incluidos bloques de hormigón y anclajes de tornillo. Gran fuerza de sujeción. |

| Estabilizadores | Amplía la anchura del muelle, aumentando la estabilidad. | Fabricado en aluminio o madera tratada; ligero, resistente y ajustable. |

| Pasarelas | Proporcionar una conexión estable entre el muelle y la orilla. | De aluminio o acero galvanizado; superficies antideslizantes y construcción duradera. |

| Anclajes de peso muerto | Añade peso al muelle, mejorando la estabilidad. | Pesado y duradero; estabilización sencilla pero eficaz. |

| Soportes ajustables | Fije diversos componentes al muelle, permitiendo su personalización. | Fabricado con metales resistentes a la corrosión. Ajustable para diferentes diseños de muelle. |

| Pilotes | Proporcionan un punto de anclaje sólido al clavarse en el lecho marino o fluvial. | Construido con madera tratada o acero. Diseñado para soportar fuerzas importantes. |

How to Choose Suitable Floating Dock Stabilizer Kits?

Para determinar qué kit estabilizador es el más adecuado para un muelle concreto y su entorno, hay que tener en cuenta varios factores. En primer lugar, hay que evaluar la profundidad del agua y las condiciones de oleaje típicas de la zona. Para aguas más profundas, es posible que necesite postes de anclaje más largos y dispositivos de flotación más resistentes para sostener la estructura. Tenga en cuenta las piezas que contiene el kit; las piezas de acero inoxidable se utilizan porque son resistentes y pueden soportar un entorno duro en caso de cualquier desafío.

Además, es importante tener en cuenta la normativa vigente en una región determinada en relación con la instalación de estabilizadores. Algunos lugares tienen leyes específicas sobre el tipo de anclajes o pilotes que pueden clavarse en el suelo. Por último, pero no por ello menos importante, se recomienda consultar a un experto o a los fabricantes para obtener la mejor recomendación en función del tipo de muelle que se vaya a utilizar. Un buen kit estabilizador marcará una diferencia significativa en la estabilidad de su muelle y, por tanto, en su uso.

¿Cómo hacer más estable un muelle flotante?

Stabilizing a dock requires a multi-layered approach. Below are eight proven methods to enhance the equilibrium of your water-based platform.

With the Use of Floating Dock Stabilizer Kit

Stabilizer kits are used to guarantee that your dock is stable by providing additional support and floatation. These are usually made up of anchor poles and floatation mechanisms which you can attach to your dock. The vertical posts that are used to support the dock are anchored to the bottom of the lake to minimize the amount of movement that the dock experiences due to wave action. These kits serve as a comprehensive upgrade to your anchoring system, often integrating specialized hardware that adapts to water level fluctuations while maintaining rigid vertical alignment. A stabilizer kit is relatively simple to install and can greatly improve the stability of your dock.

Upgrading Anchoring System

Piles that are driven into the sea or river bottom can provide your floating dock with a good place to anchor. These vertical supports prevent the lateral translation of the dock and add more support. To further upgrade the system, consider using Screw Anchors for superior holding power in sandy or muddy bottoms, or implementing Cross-Chaining techniques. Cross-chaining involves running anchor lines diagonally across the under-structure to create a “triangulated” tension system that minimizes horizontal drift. Dead weight anchors can be concrete blocks or concrete anchors that can be placed at some specific areas of the dock to increase the stability of the dock. These anchors assist in counteracting the forces developed by waves and currents that may affect the dock, thereby reducing its mobility. In terms of specific engineering parameters, it is highly recommended to use 1/4″ or 3/8″ galvanized chains to ensure long-term durability and structural strength against corrosion. Regarding weight selection, heavier anchors provide significantly better stability in rougher waters; for instance, opting for a 600 lb anchor instead of a 450 lb anchor can provide the necessary inertia to resist drifting in high-current or high-wind environments. Ensure that the anchors are of adequate size to support the environmental loads and are placed in such a way that they offer the stabilizing force in a balancedmanner.

Physical Counterweights and Balance

You can also place some weights on your floating dock to ensure that it is well anchored and stable on the water. In order to enhance support, concrete blocks or any other heavy material can be placed at the dock in a way that would offer the necessary support. To maximize effectiveness, focus on physical counterweights and balance by adding weight specifically to the bottom of the floats to lower the center of gravity of the entire structure, which assist in preventing the dock from shifting or oscillating from one side to the other. This will help to ensure that the structure is not overburdened in some areas and this will lead to the structure being damaged.

Installing Gangways and Ramps

Gangways also aid in maintaining a firm connection between the dock and the shore since they distribute the weight differently and with less oscillation. A well-engineered gangway acts as a structural lever that utilizes shore-based strength to limit lateral movement. By fixing the shore-end to a concrete bulkhead, the gangway acts as a stabilizer that restricts the dock’s side-to-side swaying. Some of the loads that are exerted by waves and water level fluctuations are well supported by a well constructed gangway hence enhancing the stability of the dock. Ensure that the gangway is well anchored and constructed from materials that would not be affected by the prevailing environmental factors.

Structural Reinforcement

To prevent the dock frame from twisting or warping under heavy wave pressure, structural reinforcement is essential. This involves installing stabilizer brackets and cross-bracing underneath the decking. By adding diagonal metal or wooden supports between the main frame members, the dock becomes a rigid “monocoque” structure. This internal stiffness prevents the individual floats from moving independently, which significantly reduces the “wavy” feeling when walking on the dock.

Additionally, you can add Stabilizing Outriggers. These are fixed transom extensions mounted at the sides of the dock and they expand the width of the dock and its buoyancy. These are like the outriggers of a canoe; they are an additional surface that reduces rocking and tilting. These can be made from wooden planks or light metals depending on the type of dock and must be securely fastened to the sides of the dock.

Adding a Roof

It is also important to note that a roof to the floating dock is not only an aesthetic addition to provide shade and shield from rain, sun, and snow but also increases the overall weight of the structure. The extra load from the roof can also reduce the impact of the wind and waves on the dock due to increased structural inertia—a heavier mass is harder to set in motion by small waves. However, it is vital to perform a wind resistance trade-off; the roof acts as a sail, so the structural design must ensure the added stability from weight outweighs the lateral forces generated by high winds. Similarly, a roof can enhance the beauty and functionality of the dock by providing shade to the workers.

Correct Load Distribution

In the context of the floating dock, the distribution of weight is crucial in the stability of the structure so as to prevent it from sinking. It is also important not to overload the dock with heavy objects on one side as this will cause the dock to become unsteady and sway a lot. Effective load distribution follows a “counterweight logic”—if a heavy piece of equipment must be on the north side, an equivalent physical weight should be added to the south side to maintain a level plane. But it is necessary to spread the load evenly across the platform so that the platform is not deformed. This entails the identification of the position of equipment, furniture and any structure within the dock area.

Fixing to the Shore

For added stability, it is advised that you anchor your floating dock to the shore using ropes or chains. For a more robust solution, utilize Stiff Arms. Unlike flexible ropes, these rigid metal arms connect the dock to a shore-based footing, allowing for vertical movement with the tides while completely preventing the dock from swinging toward or away from the bank. It also aids in preventing the dock from shifting around in a way that is undesirable due to waves and currents. For the attachments, it is recommended to use materials that are not easily corroded like stainless steel to increase the product’s durability.

Floating Dock Stability Enhancement Comparison Matrix

| Enhancement Method | Cost Level | Installation Difficulty | Durabilidad | Best Use Case |

| 1. Stabilizer Kit | Mid — High | Moderado | Alta | Commercial or high-traffic docks seeking an all-in-one professional upgrade. |

| 2. Upgrading Anchoring System | Mid — High | Alta | Excellent | Areas with high currents, large water level fluctuations, or soft bed soil. |

| 3. Physical Counterweights | Bajo | Bajo | Alta | Budget-friendly solution for docks that feel too light or “jumpy” when empty. |

| 4. Gangways & Ramps | Medio | Moderado | Alta | When shore access is required and can be leveraged to restrict lateral swaying. |

| 5. Structural Reinforcement | Medio | Alta | Alta | Docks experiencing frame warping or “wavy” sensations in heavy wave zones. |

| 6. Adding a Roof | Alta | Alta | Mid — High | Dual-purpose needs (shade + mass inertia) where wind resistance is managed. |

| 7. Correct Load Distribution | Minimal | Minimal | Perpetual | Essential daily operational logic to prevent listing or uneven wear. |

| 8. Stiff Arms (Support Arms) | Medio | Moderado | Excellent | Permanent shore-link to completely eliminate “swinging” or docking drift. |

High-tech Pro Hacks to Superior Stability

The use of water ballast in HDPE modular systems is a special method of reducing the center of gravity. You can make the boat docking system sit deeper and more firmly in the water by filling the perimeter dock floats to about 1/3 full. Nevertheless, accuracy is essential to prevent the Free Surface Effect. Blasted floats should be filled to precisely the same level and hermetically sealed otherwise the water will slosh during a tilt and generate a momentum that may, in fact, make a vessel—even a luxury yacht—more likely to capsize.

To reduce the violent rocking of the boat wakes, you may fit vertical plates or fins to the lower part of the dock’s structure. These fins do not give any buoyancy, as do the dock floats, but serve as viscous dampers. These underwater keels have to push through the column of water as the waves attempt to raise the dock, and this drag slows down the vertical and lateral movement of the dock. This design that is inspired by ships and naval establishments, is especially useful in docks that are situated in busy channels.

The best anchoring method of eliminating rolling is perhaps to maximize the waterplane area. The resistance to tilting of a dock can be increased dramatically by increasing the beam (width) of the dock, e.g. by changing a narrow I-shaped dock to an L, U, or T-shaped dock. The creation of these shapes with the use of Finger Docks or outrigers takes advantage of the second moment of area, which tends to enhance the overall stability by more than half of that of a single linear walkway. Nevertheless, these sophisticated modifications are as safe as the platform itself, and they need the precision and airtight integrity of industrial grade that is present in Hisea Dock systems.

The Hisea Dock Benefit: Designing Modular Systems to achieve high stability

In order to achieve maximum dock stability, the design of the modules themselves is as important as your smart anchoring decision. Hisea Dock has been in the business of high-performance modular systems since 2006, which are aimed at removing the typical wavy feel of floating platforms. Our blocks have connection lugs of 19mm thickness and a special four-sided groove design which greatly increases structural rigidity and lateral stability.

Our new-generation HDPE with anti-UV agents will provide users with a solid walking plank feel that will not sink over time as traditional stationary docks do, or crack like old wood planks. We suggest at least three floats wide to take advantage of our seamless design and create the most balance. From our wide online selection, we offer modules that can withstand typhoons, ensuring you have the right floating dock stabilizer kit for your needs. Our diagonal tension test has been tested at 14,389 N to ensure that it can withstand extreme pressure.

Hisea Dock has ISO-9001, CE, and TUV certifications, which means that the lifespan of the product is 20 to 30 times longer than that of the competitors. Our warranty is 5 years, 24/7, and professional anchoring advice to assist you in making your maritime dream a stable and long-lasting reality.

Preventing Critical Failures: Typical Mistakes and Stability Proven Strategies

To make your stabilization methods effective, it is important to know the common engineering and procedural mistakes that result in structural instability and early wear. The following are the pitfalls to be identified and corrected:

- Construction without checking the local legal requirements: This can cost you a lot of fines or even the removal of your anchoring system. The Department of Natural Resources (DNR) or the Army Corps of Engineers should always be consulted before the mooring system is installed to obtain the required permits.

- Not loading the weight evenly on the platform: This causes a chronic list and causes destructive and asymmetrical stress on structural connection pins. Rather, focus on center-line loading, that is, positioning all furniture and heavy equipment in a symmetrical manner to achieve a neutral static balance.

- The use of undersized or inappropriate anchors in high energy areas: Using undersized metal dock parts results in drift and possible collision damage during severe storm surges. To avoid this, adjust your anchor mass to the specific water depth and the environment with quick links and 3/8″ galvanized chains and 600 lbs or more deadweights in rougher water.

- Neglecting the effects of seasonal changes in the water level: Rigid anchoring may cause the dock to sink when the water level rises or be left high in a drought. The answer is to have adjustable tension systems or sliding winches that would enable the dock to move freely from the water’s surface.

- Adding heavy dock accessories without buoyancy: Introducing aluminum ladders, aluminum dock ladders, or jet ski lifts can form dead spots. To correct this, you can use a tiered buoyancy approach, whereby you place Double Floats (500mm height) directly under heavy dock hardware to maintain the surface level.

- Using poor quality non-marine grade hardware: This will result in quick corrosion and structural breakdown of your stabilization lines. To guarantee 1520 year life, all metal dock parts and fasteners must be made of hot-dipped galvanized steel or 316 stainless steel.

- Overloading the dock with its engineered carrying capacity during events: This causes unsafe instability and a great chance of the platform capsizing. Always handle dynamic loads by directing the guests to the center and relocating portable objects such as coolers to serve as temporary countermeasures.

Tiered Solutions at Each Level of Stability

Smart anchoring and strategic positioning is a zero-cost improvement that aims at balancing without buying new hardware by applying engineering logic. To make a dock less likely to list, you can rearrange the existing gear, e.g. benches, storage boxes, heavy coolers, etc., to bring them closer to the center-line and achieve a neutral static balance. In social events, the human factor can be proactively managed by inviting guests to sit in the middle rather than crowding the side of the dock, or by moving portable objects to the opposite end.

Simple DIY improvements using simple materials are the best when the owner wants to see a significant improvement in resistance to waves with the least amount of money. The use of DIY deadweight anchors, which include poured concrete blocks linked with 1/4 inch or 3/8 inch galvanized chains, is usually approximately 200 dollars. While this is the next best option for those on a budget, these systems require regular checks for underwater wear, they provide an instant increase in inertia. These, together with physical ballast or plain outriggers, offer a firm, cost-effective base to residential lake docks.

For those seeking long-term infrastructure, a professional piling method is the most profitable for property’s value in the long run. Heavy-duty metal stiff arms or professional piling systems may cost 5,000 or more, but they have a 20-30 year maintenance-free service. At this grade, HDPE modular systems of high quality normally have a life span of 15 to 20 years, and steel stiff arms have a life span of 10 to 15 years depending on the quality of galvanization. To commercial operators, the lower liability and longer life of a professionally anchored system is way more than the initial capital investment.

Conclusión

Finally, the dock is stable because of the equilibrium between the external energy and the internal structural integrity. You may be maximizing the area of your dock to achieve a more stable feel, strengthening the frame to remove the wavy feel, or improving your anchoring system to resist the strong currents, but the goal is the same, to provide a safe, stable, and predictable interface between land and water.

A really stable platform is a silent companion in your maritime operations. With these principles of engineering and strategic improvements, you will be able to make sure that all the transitions between the shore and the aquatic are done with complete confidence and will be a sure basis in the years to come.

FAQS

Q: How to guarantee the maximum stability of the floating dock kit?

A: Para mejorar la estabilidad de un kit de pantalán flotante, distribuya la carga uniformemente, utilice bolas metálicas pesadas y pilares metálicos, y realice comprobaciones periódicas de mantenimiento para detectar la putrefacción y asegurar las armellas, y utilice los dispositivos de flotación adecuados que puedan soportar la carga del kit de pantalán flotante.

Q: What is the maximum load that a floating dock can carry?

A: La cantidad de peso que puede soportar un dique flotante viene determinada por la construcción, los materiales utilizados y el tipo de flotadores empleados en la construcción. Por lo general, los diques flotantes son capaces de soportar miles de kilos, pero conviene consultar la documentación del fabricante. Cuando el muelle se carga con demasiado peso, se vuelve inseguro e incluso puede derrumbarse.

Q: What measures should be put in place to enhance safety on the floating docks?

A: Algunas de las medidas de precaución que deben tomarse al diseñar y construir los diques flotantes son una cubierta antideslizante, barreras protectoras y bordes bien definidos. También es importante asegurarse de que el muelle es seguro y está a salvo de peligros como tablones sueltos o clavos expuestos. Algunas de las cosas que hay que comprobar son: Comprobaciones diarias: Estas son algunas de las comprobaciones más importantes que hay que hacer en el dique flotante para asegurarse de que el entorno es seguro para su uso.