คำนำ

The development of the waterfront is regarded as the last frontier of property enhancement, where the inflexibility of the land is confronted by the unpredictable fluidity of the water. It is a refuge to a boat owner, a source of income to a resort operator and the gateway to adventure and personal enjoyment for a kayak enthusiast. Nowadays, this threshold is used in a wide range of human aspiration, and modern floating dock construction has evolved far beyond a mere wooden walkway. These buildings have become personal moorings of yachts and fishing platforms on remote lakes, but they are also essential in the business and industrial world. We observe them turning waterfronts into colorful restaurant terraces and water sports centers, or the necessary base of marine engineering work platforms and cargo logistics centers.

The building of a dock is a serious capital investment whether you are imagining a personal retreat at a weekend cottage or a specialized aquaculture platform. We will go deeper than the superficial how-to in this guide and discuss the structural integrity, legal navigation, and financial logic that it takes to create a system that does not just float, but endures. Consider this project as a connection between your way of life and the natural environment, and a delicate balance between engineering accuracy and environmental sensitivity is needed.

Why Choose a Floating Dock?

The main architectural dilemma that any waterfront owner would be faced with is: Fixed or Floating. Fixed docks provide a feeling of solid ground, but are fixed. A fixed dock may soon be a liability in an age of rising and falling tides and seasonal water level variations.

The absolute advantage of a floating dock system is that it has a freeboard at all times. Since the dock is raised and lowered with the water, the height of the platform in reference to your boat will be the same. This inherent adaptability ensures that your boat is always in reach, and your gangway at a convenient angle, whether you are in a six-foot tide in a coastal marina, or a four-foot drop in a reservoir during the dry season. Cost-efficiency wise, floating systems do not require costly pile-driving equipment in deep-water settings, and thus, it is the most scalable and flexible option in the contemporary waterfronts.

The Preparations Before the Construction Starts, the Invisible Ones

The actual process of cutting wood and screwing bolts is the last step of a successful construction. The legal and mathematical background, as well as the initial layout, is where the life of your project is determined.

Legal Compliance

You have to seek the advice of the local authorities like the DEP or DNR before you can buy one board. These agencies are more concerned with the health of the aquatic ecosystem, and may impose rules of sunlight penetration so that the dock does not kill underwater vegetation by blocking all natural light. Your design might have to be modified to meet the requirements by adding grated decking or a certain distance between planks to allow light to penetrate the waterbed. Also, your dock should not interfere with the navigational channels of the people and should be located directly within the setbacks of your property in the water. By following these local water management regulations at the outset, you will avoid expensive legal battles and make your structure an environmental asset and not a liability.

Core Mathematics: Calculation of Buoyancy

Constructing a dock without a calculation of buoyancy is like constructing a house on a sandy ground. You need to calculate the Dead Load (weight of the dock itself) and Live Load (weight of people, furniture, and equipment).

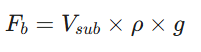

The principle of buoyancy is the basic formula of the Principle of Archimedes. To find the weight that a float can sustain when under water to a certain depth we use:

Where:

- Fb is the buoyant force.

- Vsub is the volume of the water that has been displaced.

- p is the density of the water (about 1000 kg/m 3 of freshwater).

- g = acceleration due to gravity (9.81 m/s 2).

Pro Tip: To have a stable walking surface, you want your floats to be no more than half submerged under the dead load. This makes the dock remain high in the water when the guests are stepping on it.

Materials Needed to Construct a Floating Dock

Essential Materials

Marine construction is a struggle with chemistry. Water can corrode, rot or degrade poor materials in one season. In order to construct a structure that will endure, you need to pay attention to the following five important material categories:

- Framework Materials: Framework is the most susceptible part because of the constant moisture. Apply Marine-Grade or Ground Contact (UC4A+) Pressure-Treated Wood only to withstand rot and fungal decay. A typical frame will not last five years without this particular rating. Aluminum frames are a high-end option, which is highly strong to weight ratio and inherently resistant to corrosion without chemical treatments to ensure maximum longevity.

- Decking Choices: Although natural wood such as Cedar is a classic appearance, it needs to be sanded and sealed every year. Wood-Plastic Composite (WPC) is the professional standard since it is designed to withstand UV rays and moisture and this has successfully removed the warping and splinters that are typical of natural timber. Remember that WPC is much heavier than wood which should be considered in your calculations of buoyancy.

- Critical Hardware: Standard zinc-plated fasteners will peel and rust nearly instantly in a marine environment. You have to use Hot-Dipped Galvanized (HDG) Steel or 316 Stainless Steel. In addition to plain bolts, you need to incorporate 45-Degree Corner Braces to eliminate the problem of racking (the dock bending into a parallelogram) and Heavy-Duty Hinges to enable the structure to swing safely with the waves.

- Buoyancy Components: Do not fall into the Blue Barrel Trap. The recycled barrels are unstable and cylindrical, which makes the dock roll when weight is loaded on the edge. Moreover, being hollow air-filled chambers, a single puncture will submerge part of your dock. Foam-filled HDPE Pontoons. They are flat-bottomed to ensure maximum stability and are still able to stay afloat even when the outer shell is broken by ice or debris.

- Mooring and Protection Accessories: A dock cannot be complete without the equipment to hold it and your ship. Bollards and Cleats should be through-bolted to the frame, not only to the decking, to resist storm forces. Bumpers made of high-impact PVC or rubber should be placed around the perimeter to cushion the dock and the hull of your boat. Lastly, you must have a strong Anchoring System with heavy-duty chains and anchors that fit your particular waterbed to ensure that the structure does not drift.

Essential Tools

Construction of a floating dock is an engineering project that is heavy. Due to the heavy, marine grade lumber and the corrosion resistant hardware you are dealing with, the normal household tools may not be enough. The availability of the appropriate equipment guarantees structural accuracy and durability.

The table below contains the list of the specific tools that will be needed at each of the construction stages:

| หมวดหมู่ | Tool | Role and Importance |

| Cutting Tools | Circular Saw | The primary tool for making fast, straight cuts through heavy frame beams and composite decking. |

| Hand Saw | Necessary for finishing detail cuts or creating notches in corners where a circular blade cannot reach. | |

| Fastening Tools | Impact Driver | Provides high-torque pulses to sink heavy lag bolts into treated timber without stripping the heads. |

| Socket Wrench Set | Essential for tightening large nuts on through-bolts, heavy-duty hinges, and corner reinforcements. | |

| การวัด | 30ft+ Tape Measure | Used for checking diagonal measurements to ensure the frame is perfectly square and aligned. |

| Level | Ensures the internal supports and the final decking surface are horizontally balanced. | |

| Chalk Line | Provides a long, perfectly straight visual guide to ensure decking boards and screws are uniform. | |

| อุปกรณ์ความปลอดภัย | Life Jacket (PFD) | A non-negotiable requirement for any work performed near or on the water to prevent accidents. |

| Safety Glasses | Protects eyes from flying metal shards when driving hardware and sawdust during cutting. | |

| Dust Mask | Essential to avoid inhaling chemical-laden dust when cutting treated lumber or WPC materials. |

How to Construct Your Floating Dock: A Step-By-Step Guide

Building a floating dock involves a transition between normal terrestrial carpentry and marine engineering. A professional sequence will make the structure square, stable and able to withstand the dynamic forces of open water.

Step 1: Frame Assembly and Squaring

Start by building the outer perimeter of your dock on a flat, level ground. Measure the diagonals with a long tape measure: the distance between the front-left and back-right corner should be the same distance as the one between the front-right and back-left. When these measurements are not the same, the frame is racked and will be floating at a crooked angle. When you have a perfect rectangle, then you can install your 45-degree corner braces to fix this geometry in place and then add more weight.

Step 2: Install Internal Supports

Do not depend only on the external perimeter. Install internal joists, or stringers, at 16 to 24 inch intervals. These supports are not only useful in that they offer the required mounting points to your deck boards, but also they form bays or pockets to your pontoons. You can fit these bays to the size of your pontoons, so that the flotation units do not drift laterally after the dock is in the water.

Step 3: Fit the Pontoons Upside Down

The flotation system is assembled in inverted form of the dock frame, which is industry standard. Place the frame on the ground upside down and place your pontoons in their respective bays. This enables you to attach the flanges of the pontoons to the joists with galvanized lag screws without any difficulty. This is done to make the pontoons level with the frame which is important in providing a level walking surface in the future.

Step 4: Turn Over and Take Off into the Water

The hardest part is flipping a completed frame with pontoons, since a mid-sized dock can easily be over 1,000 lbs. heavy, and a team of at least four individuals and long wooden beams are used as levers to roll the structure over. To install it, use PVC pipes under the frame to serve as rollers so that you can slide the dock into the water without any problems. Watch the momentum of the dock as it comes into the water, and keep everybody out of the way of the frame.

Step 5: Lay the Deck

When the dock is floating and has settled, then start laying your decking material. This makes sure that the installer weight is countered by the water buoyancy in the process. The gap between boards should be left at 1/8 inch to enable the water to drain and to ensure that the material does not buckle as it swells in the heat of the sun.

Step 6: Fasten the Dock Using the Anchoring System

The selection of the appropriate anchoring system is solely based on the depth of your water and the nature of the waterbed. When you are in shallow water with a soft, muddy or sandy bottom, Poles or Pilings are the best; they are very stable laterally, the dock just slides up and down the poles. Anchors and Chains are used in deeper water or where the bottom is rocky and the water level varies considerably. This is a flexible arrangement that enables the dock to move with the tide and the heavy weights on the bottom ensure that it does not drift. In docks which are very near a seawall or solid shore, Stiff Arms may be employed to keep the dock at a constant distance, so that it will not strike the shore without underwater anchors.

Step 7: Connect to the Shore

Structural fatigue is most frequently experienced at the transition between land and water. You will have to construct a strong “Abutment”–a pad of concrete or a strengthened timber header–on the shore. Join your gangway to this abutment and the dock with heavy-duty marine hinges. These hinges enable the gangway to swing up and down with the rise and fall of the water so that the connection does not snap due to the constant movement.

Step 8: Stability Testing and Accessory Installation

After mooring the dock, walk around the dock to see whether it is listing or tilting. When the platform is even, then you can do the final finishing. Attach your cleats directly to the frame so that they can take the pull of a boat, put bumpers on the sides to keep the hulls safe, and attach a dock ladder with stainless steel hardware to access the water safely.

Budget Planning: Cost Breakdown

The construction of a floating dock is usually between 15 and 35 dollars per square foot. A typical 10 x 20 dock will cost between 3000 and 7000 or more based on the quality of materials used and the location.

Budget Breakdown by Component

- Flotation (35% -45%): The most expensive. Foam-filled HDPE floats of professional grade are necessary to ensure long-term stability and buoyancy.

- Structural Frame (20% -25%): It is made of pressure-treated wood or aluminum. This involves the price of Hot-Dipped Galvanized (HDG) hardware to avoid corrosion.

- Decking Surface (20% -30%): It can be treated pine which is cost-effective or high-quality Wood-Plastic Composite (WPC) which does not require annual staining.

- Anchoring and Accessories (10% -15%): It consists of chains, weights, cleats, and bumpers that are needed to hold and protect the dock.

Cost Estimation Table (10′ x 20′ Dock)

| Tier | Configuration | Cost per sq. ft. | Total Budget |

| Basic | Wood Frame + Standard Floats + Wood Decking | $15 – $20 | $3,000 – $4,000 |

| Standard | Reinforced Frame + Premium Floats + WPC Decking | $20 – $30 | $4,000 – $6,000 |

| Premium | Aluminum Frame + Modular Floats + High-End WPC | $35+ | $7,000+ |

Essential Hidden Costs

In addition to raw materials, you need to consider a number of secondary costs:

- Permits and Shipping: Regulatory fees (100-1000+) and heavy freight charges of bulky goods such as floats.

- Shoreline Connection: The price of the gangway (bridge) and the shoreline abutment (concrete or timber landing).

- Tools and Launching: Special tools are purchased and equipment rented to transport the completed structure to the water.

A 10 percent contingency buffer is recommended to accommodate the changing material prices or unforeseen difficulties in underwater anchoring during the final installation.

Maintenance and Winterization

To ensure that your floating dock is not corroded or damaged by ice, it is important to maintain it regularly and winterize it.

Annual Health Checklist

- Hardware and Structural Integrity: Check all Hot-Dipped Galvanized (HDG) hardware to verify that it is not rusted and that all bolts are tightened that might have become loose due to wave motion. Be careful of anchor chains; friction at all times at connection points may wear away the metal links, rendering the whole mooring system unsound.

- Buoyancy Maintenance: Inspect the floats and look at them to see whether they are punctured or there is water inside. Excessive algae or barnacle growth should also be removed, which is also a bio-fouling that introduces dead weight that can result in the dock being lower in the water and exerting additional stress on the frame.

Ice Survival and Winterization

Your winter plan is based on the local water conditions and not only the temperature.

- Removal of the Dock: You have to drag your dock on shore in areas where there is moving ice (like rivers) or unstable water levels. The ice floes in such places are like a battering ram and can easily smash the frame or tear the dock off its anchors.

- When the Dock Can Remain: Docks may generally be left in the water in lee of the bays, or in deep, smooth lakes of water where the ice is at rest. In such instances, apply De-icer (Bubbler) to circulate warmer water at the bottom to the surface. This forms a liquid moat around the structure, which does not allow ice to cling to the frame or exert direct crushing force.

The construction of a dock should not be a life long maintenance. The modular systems offered by Hisea Dock offer a weatherproof and maintenance-free alternative to conventional constructions. To have a dock that is simple to assemble and even easier to winterize, check out our tough modular solutions today.

Outside the Toolbox: Why Hisea Dock is the New Standard

A conventional floating dock is a satisfying undertaking, but the hard work and the maintenance expenses in the long term can be a burden. This is the reason why most waterfront owners are resorting to Hisea Dock, a specialized manufacturer since 2006 to make the construction process easy without compromising on durability.

The how-to of dock building is redefined by Hisea Dock using a modular HDPE system. Rather than elaborate carpentry, a pair of individuals can simply put together a tailor-made dock with high-density polyethylene modules that have been impregnated with UV stabilizers to avoid aging and fading. These modules are designed to withstand extreme conditions, with connection ears of 19mm thick and a grooved design to ensure high stability. Actually, they have been tested to withstand diagonal tension of up to 14,389 N, which makes them safe even when there is a storm that can easily splinter a wooden frame.

Hisea is winter-tough, which is a standout feature to DIYers in colder climates. The recessed corners and the special buoyancy design enable the modules to be elevated above the growing ice, that is, the dock can be frequently left in the water throughout the year. Hisea Dock is supported by a 5-year warranty and international standards (ISO, CE, SGS) and is a maintenance-free product that lasts 20-30 years longer than other options, offering the ideal combination of professionalism and ease of use (plug-and-play).

บทสรุป

The construction of a floating dock is a process of transforming theory into practice. With careful planning of your buoyancy, choice of materials that can endure the chemical warfare that the water presents, and precision in anchoring, you are able to build a platform that not only increases your property value but also your quality of life.

Although the DIY path using conventional materials is rewarding, the current modular solutions such as those provided by Hiseadock provide an avenue to professional quality results without the industrial scale headache. After all, your dock is not merely a place to tie a boat, but your own personal entrance to the water. Construct it properly, and it will be a loyal friend in decades to come.

FAQS

Q: What is the cost of a floating dock?

A: The average cost of a floating dock is between 15 and 40 dollars per square foot, which gives a range of investment between 3,000 and 17,500 dollars depending on the material used, the complexity of the site, and whether you hire a professional or choose the DIY method.

Q: What are the number of barrels required to make a floating dock?

A: Typically, a standard 10′ x 10′ floating dock will need 4 to 6 plastic 55-gallon barrels, which will give the structure about 450 pounds of buoyancy to safely hold the weight of the structure and its occupants.

Q: How long does a floating dock last?

A: HDPE modular systems have a service life of 20 to 30 years on a floating dock, aluminum frames have a service life of 30 to 50 years, and pressure-treated wood has a service life of 10 to 15 years, depending on environmental exposure and frequency of maintenance.

Q: What is the depth of water required in a floating dock?

A: Floating docks need a minimum of 3 to 5 feet of water depth, with enough clearance to avoid the floats grounding with seasonal changes in water level and to keep the system out of submerged debris.