Introduction

The boundary between land stability and water movement has been a major challenge to marine engineering. Conventionally, mankind tried to overcome the water pushing huge piles into the sea floor, erecting permanent constructions that resisted the waves. But with the development of our knowledge of fluid mechanics and material science, a more beautiful solution was found: the floating boat dock.

A floating dock does not struggle with the water, as its fixed counterparts do. Choosing the right dock for a waterfront property is essential for enjoying various water activities. In a time when the increasing sea level and unpredictable weather patterns are becoming the new reality and not an exception, the knowledge of how these structures work is no longer a niche concern of harbor masters. It is a basic need to the boat owners, the developers of resorts and the industrial operators who need to have a dependable access to the water. This paper gives an in-depth discussion of the physics, elements, and selection criteria that characterize the modern floating boat dock system.

What are Floating Docks?

A floating dock is, at its simplest, a platform mounted on buoyant pontoons or modular units, like high-density polyethylene (HDPE) cubes, which are placed directly on the surface of the water. A floating dock is a mass that is floating and in contrast to a fixed pier, which is held in place by permanent pillars (piles) that are embedded in the seabed, a floating dock is a floating mass that rises and falls with the surrounding environment. These systems are as simple as wooden platforms to be used in lakes, and as complicated as modular systems that are used in international ports and jet skis launching.

This floating design renders the floating dock water-level agnostic. A fixed dock in a high-tide or seasonally high and low water area can be submerged in floods or leave a ship far below the deck in low water. Nevertheless, since a floating dock is anchored vertically and is not attached to the seabed, it follows the water surface exactly. This makes the distance between the water and the dock floor, the freeboard, constant. The system ensures a safer and more reliable interface to boarding and deboarding the boat at all times by maintaining the dock at a constant height relative to the hull of the boat.

The gangway coordinates the transition between the stationary land and this dynamic platform. This bridge is commonly attached to a hinge on the shore and the dock-side is mounted on rollers or sliding pads. The gangway pivots as the water level rises or falls, and the dock moves up and down to adjust the slope of the gangway. This mechanical coordination enables the gangway to absorb the vertical drop and in effect close the gap between the fixed land and the moving water surface without affecting the stability or safety of the walkway.

How does a Floating Dock Work?

The working principle of a floating dock is a brilliant piece of classical physics, which is based on an unceasing balance between the downward gravitational forces and the upward hydrostatic pressure. This is controlled by the Principle of Archimedes which says that any object that is placed in a fluid is supported by a force that is equal to the weight of the displaced fluid. In a floating dock system, the floats (usually airtight shells of HDPE) are designed to be much less dense than water. Since they push aside a mass of water that is much heavier than the structure itself, they produce the enormous upward force that is required to keep them afloat.

To see how efficient this system is technically, we may consider the physics and data of a typical modular float:

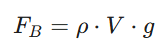

- The Buoyancy Formula: The force of upward (FB) is determined as follows:

P = Density of water (density of fresh water is about 1000 kg/m3).

V = Volume of displaced water

g = Acceleration due to gravity (9.81 m/s2 )

- Standard Unit Data: A typical modular float cube (500 x 500 x 400mm) has a total volume of 0.1 m3.

- Displacement Capacity: This one cube is able to displace 100 kg of water in fresh water.

- Net Buoyancy: The float itself is only approximately 7 kg, which gives it a theoretical net lift of 93 kg.

- Engineering Safety Margin: Professional installations are normally engineered to a 50% load factor, which is sufficient to make the dock stable and well above the waterline even when it is fully loaded to its maximum intended Live Load.

This is a balance between buoyancy and gravity that enables the dock to be a self-adjusting platform. It has two different types of weight: Dead Load (weight of the frame and decking) and Live Load (passengers or equipment). When an individual gets on the dock, the system temporarily loses balance as the force of gravity acts more. The dock reacts by sinking a little further, pushing out another amount of water. When the weight of this new displaced water is precisely equal to the weight of the person, the dock is in a new state of equilibrium and stabilizes. This hydraulic response makes the dock level and stable no matter the distribution of weight.

Key Categories: What are the Differences between the Various Docks?

Although all floating docks are based on the concept of buoyancy, the structural engineering of the docks defines the way they support loads, environmental forces, and the needs of a particular vessel.

Pontoon Systems (Interlocking Cube Technology) HDPE Modular

The ultimate in versatility is the modular system, which consists of single, blow-molded High-Density Polyethylene (HDPE) cubes that are joined together with high-strength composite pins. This is in contrast to a single rigid structure, which forms a honeycomb type matrix that enables the dock to spread weight among hundreds of individual air chambers. The system employs interlocking lugs on the corners of every cube to form a flexible yet extremely powerful platform that can roll with the wave energy instead of opposing it, which eliminates structural snapping in rough waters. This modular design can be used to create a v-shaped entry channels, which allows users to pull their vessels onto the dry dock directly, which makes them ideal in PWC and Jet Ski ports. They are also suitable in irregular walkways in narrow and winding paths where conventional docks are not feasible and are the industry standard in temporary work platforms, floating stages, and aquatic event flooring.

Framed Floating Docks (Rigid Structural Systems)

Framed docks are designed to give the impression of a fixed, terrestrial building using a heavy-duty rigid skeleton, usually marine-grade aluminum, galvanized steel, or pressure-treated timber, which is bolted to large-volume encapsulated floats commonly referred to as poly-tubs. The frame is a structural truss that gives the dock high torsional rigidity, which does not cause it to bend when stepped on. These systems offer a significantly higher capacity to carry heavy decking materials by offering buoyancy with a few large-scale floats instead of numerous small ones. This is why they are best suited in residential lakefronts where homeowners desire high-quality finishes such as Wood-Plastic Composite (WPC) or hardwood decking. They are also well adapted to commercial marinas and busy public piers, where they offer stable mooring posts to large cruisers and yachts, which need a totally rigid walking surface to access and be comfortable.

Floating Dry Docks (Pneumatic & Ballast Systems)

The most technically complicated systems are floating dry docks, which are created with the purpose of protecting and maintaining boats with the help of active displacement control rather than constant buoyancy. These docks are worked by means of internal ballast tanks; the tanks being filled with water the dock sinks below the water line so that a boat may pass over it. When the vessel is in place, high capacity air pumps pump out the water in the tanks, and the dock rises and lifts the entire vessel entirely out of the water. This is necessary to protect the hull of saltwater, because it inhibits the growth of barnacles, osmosis and corrosion without the use of toxic anti-fouling paint. These systems also offer a means of keeping a boat in the water and keeping the hull 100% dry during the off-season and also provide high-speed vessel owners with easy access to propellers and outdrives to clean and inspect them regularly.

Floating Dock Components

The selection of materials used in each component is important to make the corrosive marine environment long-lasting. The following is a simplified description of the four fundamental components of a high-performance floating dock.

- Floats and Pontoons: The dock is supported by the floats which give the required buoyancy to keep the freeboard constant. The material of choice is High-Density Polyethylene (HDPE) due to its impact resistance and salt corrosion resistance. Although hollow floats are a cheaper alternative, professional systems use EPS foam-filled floats. These units are filled with closed-cell expanded polystyrene that makes sure that in case the outer HDPE shell is pierced by debris or ice, the float will not take in water and sink.

- Structural Frame: The frame gives the structural strength to withstand environmental stressors. In hard systems, marine grade aluminum is the material of choice due to its light weight and rust resistance whereas galvanized steel is employed in industrial heavy-duty systems. In modular systems, the structure is formed by the aggregate interlocking of the HDPE cubes, and there is no separate frame. This combined design enables the dock to be a single, unified structure that is able to distribute weight and stress efficiently over its entire surface.

- Decking Materials: The decking is the exposed walking surface and therefore it should not rot, degrade under UV, or be slippery. Although traditional wood is beautiful, it is very expensive to maintain because it can be splintered and rotten. Contemporary substitutes are Wood-Plastic Composite (WPC) and anti-slip HDPE plastic that provides the appearance of wood but with much greater strength. In the case of modular docks, the decking is typically a molded, textured surface that is part of the float, which offers better traction even when wet and avoids the use of secondary surfacing.

- Connection Hardware and Couplers: Connection hardware is what makes the dock stay in place and yet be able to move. In modular designs, the interlocking lugs of each cube are connected by high-strength composite couplers and pins. These connectors are designed to behave as hinges and the platform to flex and absorb wave energy instead of breaking under tension. The flexibility of reconfiguring, expanding or reducing the footprint of the dock is also offered by this modular connectivity as the needs of the user change.

Stability and Anchoring: Why not Floating Away?

A floating dock should be able to withstand strong lateral forces of wind, current, and wave action to keep it in its intended location. A dock without a strong anchoring system is more or less a huge sail, and it can blow away a long way out of its proper course. The anchoring mechanism acts as the root system of the dock, which gives horizontal restraint and allows the required vertical movement that is needed by the fluctuating water levels.

Primary Anchoring Mechanisms

The anchoring selection is mainly determined by the depth of the water, the composition of the seabed, and the harshness of the environment.

- Piling Pipes and Guide Hoops: This is the most firm technique of permanent installations. Piles made of steel, concrete or wood are drilled deep into the sub-aqueous soil. These piles are connected to the dock through pile guides or rollers. These elements enable the dock to move up and down with the tide but not to move sideways. Rollers are especially useful in high-friction settings, where the dock will not get stuck on the pile when the water level drops quickly.

- Dead Weights and Cable Systems: In deep-water conditions where driving piles is either physically or economically infeasible, heavy concrete blocks (dead weights) are placed on the bottom of the sea. They are attached to the dock with galvanized chains or stainless steel cables, which are frequently in a criss-cross (X-pattern). This geometry offers tension in several directions, with the dock in the center and reduces the swing, but still allows the dock to swing up and down in a predefined arc.

- Stiff Arms (Shore-to-Dock Linkage): Stiff arms provide a mechanical solution to docks that are close to a fixed shoreline or bulkhead. These are metal poles of heavy weight, hinged at the shore-side and the dock-side. They serve as a spacer that maintains a constant distance between the dock and the bank, and the hinges enable the arm to swing up and down with the change in water level.

Lateral Stability and Torsional Resistance

In addition to just being stationary, a dock should not tip over, which is referred to as lateral stability. This is mostly a role of the footprint or width of the dock. A broader dock is more difficult to roll as the metacentric height is greater, and it is much more difficult to roll when the weight is concentrated on the outer edge. This is essential in safety when boarding the vessel or when heavy equipment is transported over the deck.

The couplers are the unsung heroes of this stability, especially in modular systems. These specialized connectors are like biological joints, which offer the controlled flexibility required to absorb the kinetic energy of waves. In the case of a perfectly rigid dock, the unremitting torque and shear forces of a rough sea would ultimately result in the breakage of the structure or the failure of the mounting hardware. Rather, the couplers enable the dock to bend and absorb energy across the entire array of floats, ensuring structural integrity without affecting the stability of the walking surface.

Floating vs. Fixed Docks: The Right Engineering Decision

The choice of floating and fixed dock is a very important engineering decision, which is based on the conditions of the water, the environmental laws, and the particular use requirements. Although fixed docks provide a feeling of permanency, floating docks offer unmatched flexibility to changing conditions.

In order to select the appropriate docking solution, one must compare the main engineering and operational differences between floating and fixed systems. The table below gives a comparative analysis.

| Feature | Floating Dock | Fixed Dock |

| Water Level Change | Excellent: Naturally rises and falls with water levels to maintain a constant freeboard. | Poor: Can easily be submerged or left too high as water levels fluctuate. |

| Installation Cost | Generally Lower: Features a modular design that is fast to install without heavy machinery. | Higher: Requires expensive piling equipment and significant labor for seafloor penetration. |

| Ice Conditions | Superior: High resilience; the structure can “heave” with ice or be removed entirely. | Vulnerable: Susceptible to “ice jacking,” where expanding ice pulls piles out of the seabed. |

| Environmental Impact | Minimal: Does not disturb the seabed or local aquatic habitats during or after installation. | Significant: Requires permanent seafloor penetration and displacement of the ecosystem. |

| Stability | Flexible: Feels “moving” underfoot; stability relies on proper dock width and buoyancy design. | Stationary: Extremely stable and rock-solid as it is anchored directly into the ground. |

| Maintenance | Accessible: Individual modules can be detached or towed to shore for easy, cost-effective repairs. | Complex: Repairs are difficult and often require divers, barges, or underwater construction. |

| Layout Flexibility | High: The modular nature allows for easy expansion, relocation, or reconfiguration at any time. | Low: Once pilings are driven, the layout is permanent and nearly impossible to alter. |

Floating docks offer a very versatile and economical alternative to fixed systems by naturally adapting to changing water levels and avoiding ice damage by being able to heave or be removed. Compared to fixed docks, which need heavy machinery to install, these modular systems are much less expensive to install and maintain since the units can be towed to shore easily to be repaired without involving professional divers or barges. In addition to financial savings, the modular design provides unparalleled flexibility in future reconfiguration or expansion, and does not harm the local ecosystem by permanently disturbing the seabed and displacing habitats as would be necessary with traditional pilings.

What is the best Floating Dock to Select?

The choice of the most suitable floating dock is a strategic engineering choice that considers the environmental factors and certain functional needs. In order to have a long-term maritime investment, you need to consider four important dimensions, which include water dynamics, load requirements, total cost, and climate resilience.

Water Environment and Wave Energy Assessment

The initial one is a strict assessment of the energy level of your water. Simple modular blocks are normally adequate in calm and sheltered lakes. But when you are in high-energy conditions, such as rivers with strong currents or coastal zones with tidal waves, structural flexibility should be your priority. Modular HDPE systems have interlocking connections, which serve as hinges, unlike rigid docks that can break under pressure, which enables the platform to bend and absorb wave energy. When your site has a long fetch (distance wind travels over water) seek systems with reinforced connection ears – e.g. 19mm thickness – to withstand the consequent tensile stress.

Usage Requirements and Load Capacity

The required buoyancy and structural rigidity are directly dependent on your intended use. A dock to launch kayaks must have a low freeboard, whereas mooring a 10-ton yacht must have a high displacement and a stiff frame to hold it in place. To ensure that the dock does not tilt or submerge under the weight of passengers, furniture and equipment, it is necessary to compute the maximum Live Load which is the weight of the passengers, furniture and equipment. In the case of Personal Watercraft (PWC), special drive-on ports with V-shaped entry channels are suggested to ensure that the hull remains dry and free of marine growth.

Total Cost of Ownership (TCO) vs. First Budget

In budgeting, you need to look beyond the first price on the sticker to the TCO in the long run. Although the initial cost of traditional wooden docks might be less, they need a lot of labor-intensive maintenance, including staining and rot replacement. Conversely, HDPE modular docks provide a set and forget solution. These systems are virtually maintenance free and can last 20-30 percent longer than industry options since they are resistant to UV degradation, salt corrosion and splinters. The maintenance savings usually make HDPE the cheaper option over a 10-year lifecycle.

Adaptability and Ice Management of Climate

In areas where the water bodies are frozen, your dock should be designed to withstand the pressure of ice. One of the key benefits of modular HDPE systems is that they can heave; the tapered shape of the system enables it to pop up on the top of the ice instead of being crushed by it. Conversely, fixed docks are very susceptible to ice jacking, whereby growing ice may drag piles off the seabed. When you are in a location where ice is very active, the main consideration is to have a modular system that can be easily detached and towed to the shore to store it during winter.

Why Hisea Dock is the Industry Standard of Reliable Flotation

Hisea Dock has been closing the gap between theoretical buoyancy and actual maritime resilience since 2006. We use a new generation of High-Density Polyethylene (HDPE) with new UV-stabilizers, which means that your system will not fade away or deteriorate as time goes on, like in the marine environment. This is a specialized material science that leads to a structural lifespan that is 20-30 percent higher than industry offerings.

Our modules are designed with 19mm-thick connection ears to make sure that your dock can withstand the kinetic energy of waves that are relentless and have been tested in rigorous diagonal tension tests to withstand a force of up to 14,389 N. The dock engine is also optimized by four-sided grooves to provide better lateral stability and threaded end-caps to ensure permanent, airtight seal to provide maximum buoyancy.

This engineering superiority is backed by a worldwide infrastructure that is fast and reliable. Hisea Dock has four modern production lines and serves its customers in more than 80 countries and regions. We know that maritime projects are time-sensitive, that is why we have industry-leading lead times: only 710 days to place a standard order and 1015 days to create a tailored solution. Supported by a 5-year warranty and global certifications (ISO-9001, CE, SGS, TUV), Hisea Dock offers the manufacturing capacity and expert advice needed to transform the complicated science of flotation into a maintenance-free reality.

Legal and Regulatory Guidelines: The Knowledge of Licenses and Regulations

It is important to know the local regulations of your shoreline before placing a floating dock. Most lakebeds are treated as a public or a protected property and therefore, getting the right permits early will save you the fines and make sure that your dock is in compliance in the coming years.

- Permits and Licensing: You should ensure that you have the authority of your waterway before you begin installation. The lakebed is generally regarded as public property in most places, and you will require a permit with local zoning boards, environmental agencies (such as the DNR), or even the Army Corps of Engineers in navigable waters. To get it done faster, see whether your project is a General Permit, which are pre-approved of small residential floating docks and require a lot less paperwork than custom permanent structures.

- Riparian Rights: You have the right to own the shoreline, but your riparian rights are restricted by the demands of the people and your neighbors. Your dock should not obstruct the passage of the waterways or reach so far that it will be a danger to the passing boats. Also, in most jurisdictions, there is a buffer zone (usually 15 to 25 feet) between the underwater extension of your property line and the waterfront to make sure that you are not encroaching on the waterfront of your neighbor or obstructing his or her view.

- Environmental Impact: The largest obstacle in dock approval is usually environmental protection. Here, modular floating docks are at a great advantage. Floating docks have little effect on the ground, unlike permanent piers which must be jetted into the ground, which destroys fish spawning grounds and causes silt to rise to the surface. Moreover, HDPE (high-density polyethylene) is used, which means that no toxic chemicals or wood preservatives will enter the water, which is why it is a good option among environmentally conscious regulators.

Floating Docks Installation and Maintenance

The main benefit of a modular system is its efficiency. An average Hisea Dock can be assembled in a few minutes by only two individuals with simple tools and does not require costly contractors or heavy equipment.

The Installation Process

The assembly is typically initiated on the shore or in shallow water. The cubes have four connecting lugs on their corners, which are meant to fit and fit with the other units. After these lugs have been layered, a high strength connecting pin is inserted through the center. With a special T-handle wrench, you just have to make the pin turn 45 degrees to secure the cubes in one, solid platform. After the main structure is finished it is towed into place. The final thing is to stabilize the dock with an anchoring system that suits your setting, which is usually internal piling pipes in stable lakebeds or heavy-duty anchor chains and deadweights in deeper or more tidal waters.

Maintenance and Longevity

The fact that it almost completely eliminates maintenance is one of the main reasons why owners switch to HDPE (High-Density Polyethylene). These modular cubes are chemically inert and UV-stabilized unlike wood, which needs to be stained seasonally, or steel, which rusts over time. Regular maintenance is restricted to a regular power wash to clean the surface algae or bird droppings. Since the material is not rot or splinter, structural reinforcements are unnecessary with time. We only suggest a seasonal check of your anchor lines tension, and the connecting pins, to be firmly locked, particularly after a severe storm or a change of ice in the winter.

Conclusion

Floating docks are a success of adaptive engineering. We have adopted the concept of buoyancy and made use of the contemporary polymers to make structures as strong as they are pliable. Be it a private boat owner seeking a safe slip or a commercial developer constructing a floating restaurant, the science is the same: balance, displacement, and durability.

When you invest in a high quality system with a manufacturer that has proven itself such as Hisea Dock, you are sure that your gateway to the water will be stable, safe and sustainable over decades to come. With the tides still shifting, the floating dock is the most reasonable connection between our lives on land and our escapades on the water.